Method

- Analysis and project management

We engage early in the process, analyzing logistics, flow, and volume to determine the most effective packaging solution, whether it’s for single-use or a return system. - Design and development

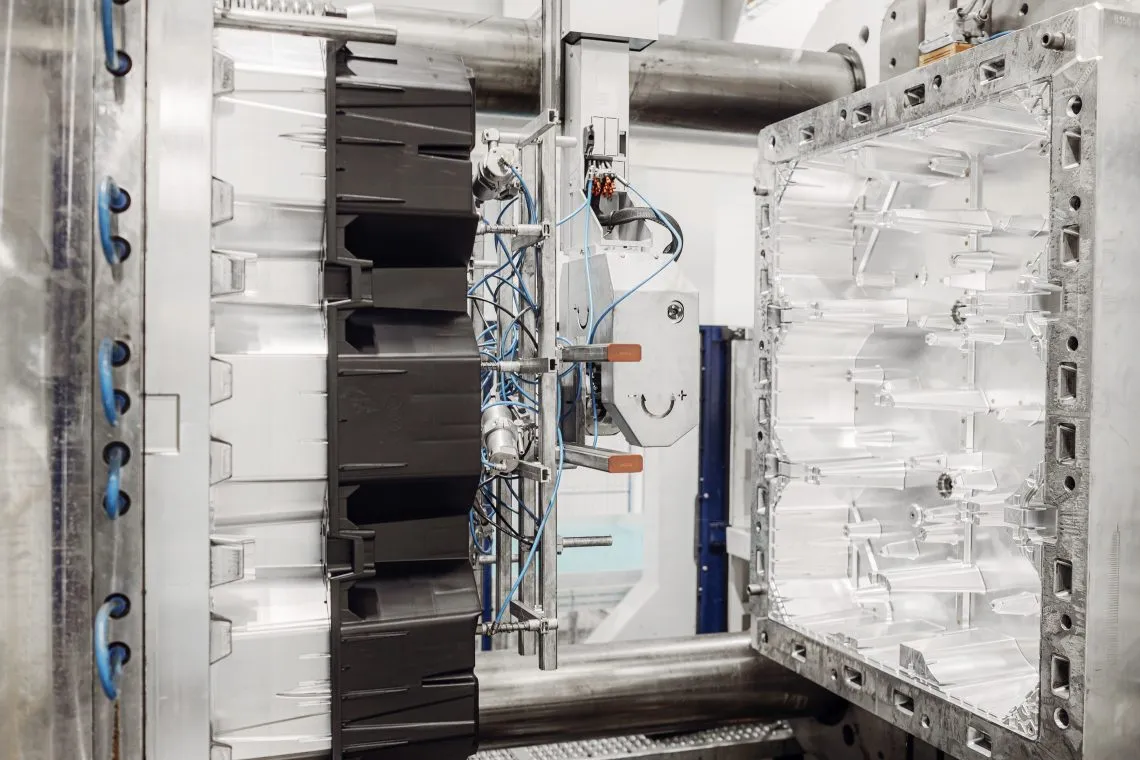

This phase involves creating construction drawings and 3D prototypes, which are essential for testing and further development before production. - Specialized production

Utilizing unique molding tool technology we offer high profitability even for large and small series production. 35 production lines in our plants covering a set up from 250 to 2100 ton machines. - Recycling hubs

Turning the trays into small plastic ships at our local recycling hubs is securing that we could return our material over longer distance. 90% of the normal return freight is directly reduced.

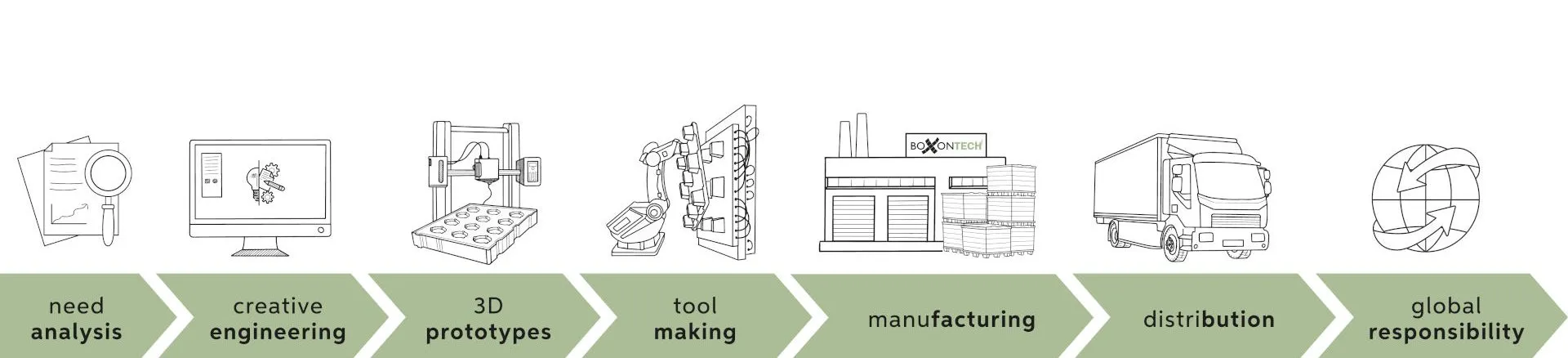

Process steps

At the outset of our process, we engage in a deep collaboration with you, incorporating your ideas and feedback through interactive checkpoints to tailor cutting-edge packaging solutions that precisely meet your needs.

We start by analyzing your specific needs, considering global flows, sustainability demands, and streamlining. Our expertise in the automotive industry informs our project management, ensuring tailored solutions for each client.

Our design process begins with thorough material collection. We use construction drawings and 3D prototypes as a basis for testing and development, ensuring a seamless transition to production.

Using advanced molding tool technology, we replace traditional manufacturing methods. This allows for profitability for tooling investments even for rather small volume requirements where injection molding normally not is the natural packaging alternative.

Ongoingly growing production to secure that our customers always get clean produced packaging delivered to their sites for agreed volume planning.

Our growing network of local BoxonTech recycling hubs is securing that we could support customer flows on a global scale, both inland flows and oversea shipments. To close the material loop exemplify our commitment to cost reduction, quality enhancement, and sustainability fully.